Facility

Our Facility

Factory Location and Size

Blue Lake Dairy Group is situated at 31203 Princes Highway, Tantanoola in the state of South Australia. This location is approximately 410 Kilometres southeast of Adelaide, South Australia, and 450 Kilometres west of Melbourne, Victoria. South Australia’s second largest city, Mount Gambier, is only half an hour away and Blue Lake Dairy sits in the area known as the Green Triangle in recognition of its fertile grasslands.

The factory is located on 406,000 m2 of land, of which the office area and the production plant is about 5,500 m2, and about 4,000 m2 of insulated warehouse area.

We produce 20,000 tons

of milk powder every year

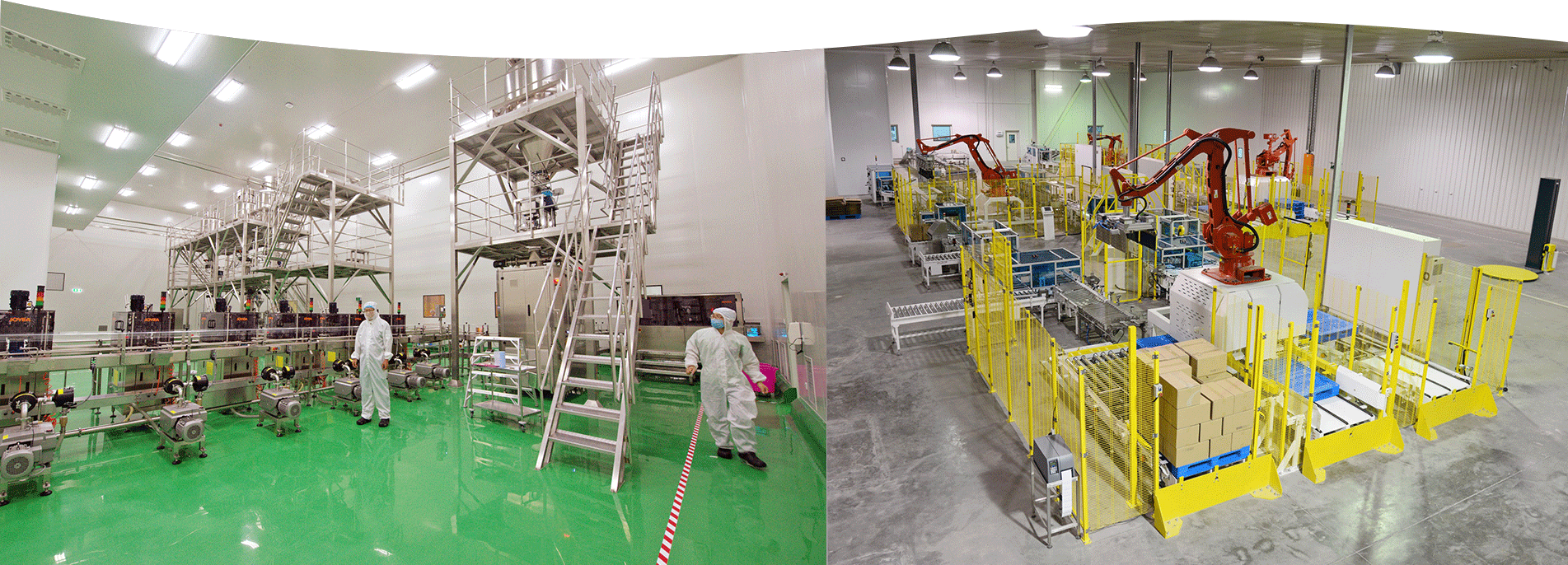

Factory Function, Planning & Design

There are six planned production lines, consisting of 2 can (rigid packaging) lines, 2 vertical bag lines and 2 sets of double sachet lines, with four pneumatic dry mixers and positive pressure transmission systems.

The factory’s planned annual output capacity is 30,000 tons

The equipment in place for the first stage includes 1 can line with 7 seaming machines, 2 sets of vertical bag lines, 1 set of double sachet line (not including automatic cartoning machine) and 2 sets of pneumatic dry mixing and positive pressure conveying systems.

Advantages of the Geographical Location

The factory is located in the southeast region of South Australia, which is South Australia’ s highest dairy production area. Each cow can produce up to 8,000 litres of milk per year. The milk is rich in nutrients with cream contents of up to 4.0% and protein contents of up to 3.6%. This is 20-30% higher than other regions of Australia.

The region’s high yield advantages are as follows:

1.

The opportunity for more farm land to be converted to dairy use, potentiallyincreasing the area’s milk production from 350 million litres to 1 billion litres.

2.

A good climate with the annual average temperature of 16°C-25°C, and average annual rainfall of 700 mm, which from late April to October is between 50-100mm per month.

3.

Good irrigation conditions, rich in groundwater resources. 80% of dairy farms with irrigation systems.

4.

High quality feed and forage for dairy production, including ryegrass, alfalfa, wheat, pea and other hay feed.

The Source of Milk

The suppliers of the packaged milk powder required for first stage’s packaging plant are located in the Warrnambool area of Victoria, 180 kilometres from the factory. Warrnambool is one of the leading milk supply areas, with large companies such as Warrnambool Cheese and Butter, Fonterra and Burra Foods all operating from this part of the Green Triangle.

After the completion of a spray dryer facility the liquid milk will be sourced mainly from over 110 pastures in the surrounding area.

The Advantages of Factory Layout, Size & Production Line

1. The factory design and layout not only meets the Australian dairy industry standards, but is also designed in accordance with high standards set by the Chinese infant milk powder industry. The factory has first and second change rooms, an air shower, laboratories and other professional dairy infrastructure facilities.

2. The factory’s GMP clean zone is around 1,000 square meters. With this area and the quasi clean room, raw materials storage, finished products storage, insulated warehouses etc, the factory is the largest milk powder packaging facility in Australia.

3. The Capacity of Production Line

The packaging production lines have the most advanced auto packing machines in Australia.

As such, it can produce:

• Cans (400 – 1000g) with either high or flat caps;

• Bags (400-1000g); and

• Sachets (25 – 40g).

From the raw materials entering the production zone to the stacking of the finished pallets, this greatly reduces the number of personnel required, which further reduces the risk of potential contamination and operational mishaps.